Biogas has a varying content of CH4, usually around 50 volume percent. It is possible to upgrade biogas, decreasing the content of CO2 or increasing the content of CH4, and obtain so-called biomethane, i.e. gas with the quality of natural gas. Biomethane can be used as fuel for bioCNG motor vehicles or pressed into the gasworks network.

There are several techniques of upgrading biogas to biomethane. The most common technologies to process biogas include high-pressure water cleaning, chemical absorption, PSA, cryogenic separation and membrane separation. Each technology has its advantages and disadvantages that often depend on the place of biogas production, the capacity of processed biogas etc. The advantages of membrane separation mainly include the simplicity of the process, low energy demands, low maintenance requirements, independence on the changes in the biogas composition and no need to use any liquids and to regenerate or eliminate them. On the whole, membrane separation is environmentally friendly.

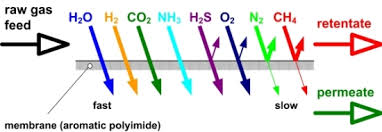

The principle of membrane separation is based on varying permeability of molecules through the membrane. Some molecules, such as CO2, pass through the membrane and get to the permeate side. CH4 does not pass through the membrane and stays on the retentate side. Thus, a flow rich in CH4 is generated.